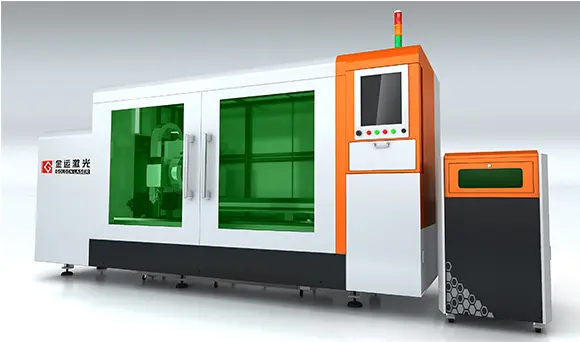

Golden Laser CNC laser cutting machine types vary from thin tubes to thick tubes, small tubes to large tubes, regular shape tubes to special-shaped tubes, or standard laser pipe cutting machine types to custom models, and more. As a leading famous laser cutting machine supplier, we provide a wide range of opportunities and possibilities to meet different CNC laser tube cutter demands.

Are you looking forward to a CNC laser tube cutting machine to help your metal tube processing business? Golden Laser will be customer-oriented and create value for customers. Golden Laser will provide you with professional CNC laser cut pipe solutions and services to suit your 2D/3D laser cutting projects within your budget.

Golden Laser Smart Laser Tube Cutting Machine, the leader of the new generation laser tube. The smart laser tube cutting machine series meet all requirements from pipe fittings to steel construction. The automation model guarantees maximum productivity and fast production changes.

Small Tube Laser Cutting Machine is designed for small and thin thickness tube processing. Minimum size, maximum production rate. Perfectly solve the tube processing with a diameter within 100 mm.

3D 5-axis Laser Cutter has a swing cutting head so it can achieve 45-degree cutting. Give your special-shaped pipe or profile cutting more possibilities.

Cost-effective fiber laser tube cutting machine P2060B, your start-off laser tube cutting machine. Flexible matching of various metal tube types, the most productive fiber solution for your metalworking business. Tube range ∅min. 20 mm - max. 200 mm.

Round Tube Laser Cutting Machine is special for processing round tube type pipes. Please choose it for high precision and high-efficiency work.

Heavy Duty Tube Laser Cutting Machine is suitable for processing ultra-long and ultra-heavy pipes. Save time and labor for you.

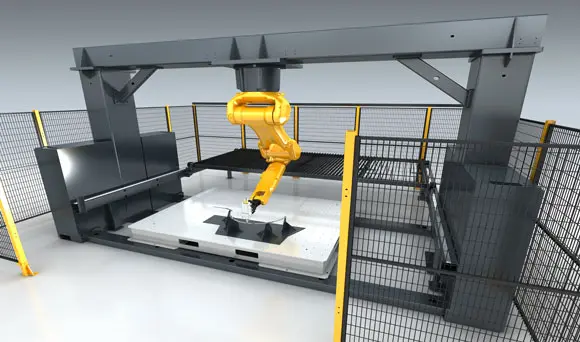

Golden Laser FMS consists of CNC laser cutting systems, which can realize 3 or more online production, that is, 3 or more fiber laser cutting machines or laser robots, polishing machines or other machines can operate simultaneously.

Golden Laser 3D Robot Laser Cutting Machine, you can flexibly choose the installation position of the robot, whether it is vertical or gantry inverted pile, and you can also choose a fully enclosed protective cover. One machine for two purposes, easy to solve 2D laser cutting and 3D laser cutting.

Customized flexible laser solution for the broadest tube processing capability.

Portable, easy to operate, economical, and intelligent laser machine. A cost-effective laser machine integrating laser welding, laser cleaning, and laser cutting.

Name | Smart Laser Tube Cutting Machine | Small Tube Laser Cutting Machine | 3D 5-axis Laser Tube Cutting Machine | Cost-Effective Laser Tube Cutting Machine | Round Tube Laser Cutting Machine |

Model (optional) | i25A i35A | S12plus | i25A-3D i35A-3D | F20 | S12R |

Tube Cutting Capability | Φ20mm - Φ200mm (350mm); □20mm * 20mm - □140mm (240mm) * 140mm (240)mm | Φ10mm - Φ120mm; □10mm * 10mm - □80mm * 80mm | Φ20mm - Φ200mm (350mm); □20mm * 20mm - □140mm (240mm) * 140mm (240)mm | Φ10mm - Φ120mm; □10mm * 10mm - □140mm * 140mm; Channel steel 16#; I-beam 16# | Φ10mm - Φ120mm |

Power | 1500W- 6000W | 1500W- 4000W | 3000W- 6000W | 1500W- 3000W | 1000W- 3000W |

Length of Tube | Up to 12m (customized) | 6500mm | Up to 8500mm (customized) | 6500mm | 6000mm |

X/Y-axis Positioning Accuracy | 0.02mm | 0.05mm | 0.02mm | 0.03mm | 0.05mm |

Max Rotate Speed | 160r/min | 150r/min | 130r/min | 130r/min | 80r/min |

Weight of Single Tube | 225kg (Φ200mm*8mm*6000mm); 600kg (Φ300mm*10mm*8000mm) | 85kg (Φ120mm*5mm*6000mm) | 225kg (Φ200mm*8mm*6000mm) | 150kg (200mm*8mm*6000mm) | 25kg |

Max Weight for Auto Feeder | 2.5t | 2t | 2.5t | 1t | 0.6t |

Representative Application Industries | Automotive parts; Pipe fittings; Photovoltaic bracket | Fitness equipment; Metal furniture; baby trolley | Automotive; Metalworking; Structural; Aerospace | Metalworking; Motorcycles | Steel pipe elbow; bathroom accesories |

The utilization rate of CNC laser cutter for tube in industrial production is getting higher and higher, inseparable from our lives. So do you know how does a CNC tube cutting laser machine work?

A CNC tube laser machine is emitted from the laser, passing through the optical path system and focusing on the laser beam with high power density. The laser beam is irradiated on the metal pipe or sheet metal surface so that the workpiece reaches the melting point or boiling point, and the high-pressure gas coaxial with the beam melts or vaporizes the metal. As the relative position of the beam and the workpiece moves, the metal tube or sheet metal will eventually be cut.

Laser cutting is replacing the existing mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, unlimited cutting mode, automatic typesetting to save materials, smooth cutting, and low processing cost. It is gradually replacing traditional metal cutting tools.

A CNC laser tube cutter machine is usually suitable for laser tube cutting and metal sheet laser cutting. Here, we focus on how to use a CNC tube laser cutting machine.

Technicians need to be trained to operate the CNC tube laser cutting equipment;

Before operating the industrial CNC laser cutting machine, you need to type the cutting graphics in the CAM software and then import the obtained NC file into the operating software;

Prepare the metal material to be cut, then by manual or automatic feeding mode;

Adjust laser pipe cutting parameters; Prepare laser cutting gas; Confirm the status of laser cutting head;

Press the start button to start pipe cutting;

After the cutting is completed, check the quality of the finished pipe fittings and the cutting accuracy. If the requirements are not met, check and adjust the set parameters.

Why choose a high-quality laser cutting machine for the tube? Saving time and reducing the number of parts, you can laser cut tubes of any section shape: round tubes, rectangular tubes, profiles with open or profiled sections, and extruded tubes and profiles. Our fiber laser cutting machines have a rich library of tube splicing methods that can be assembled without screws or welding.

As a leading CNC tube cutting machine supplier, Golden Laser's fiber laser machines for sale are used by more and more partners in the automotive industry, metal furniture, baby carriages, medical beds, photovoltaic brackets, metal display racks, warehousing logistics, pipe fittings, and other industries.

At Golden Laser, you can find the laser cutter solution that suits you!

There are three key questions to ask yourself when deciding on a machine: What is your primary use ( cutting, engraving etc. ) Which materials and type of tubes are you looking to work with?

Laser cutting machine speed is fast, the section is smooth without burrs, no secondary processing is required, and the precision is high. Still, the price is higher than the plasma cutting machine.

Please send us a message to inform us of your laser cutting requirements, and our laser experts will contact you shortly about the customized laser solution.

Focusing on "creating value for customers," Golden Laser insists on providing worry-free pre-sale, in-sale, and after-sale services.

After more than three months of consideration and investigation, the P3080A fiber laser cutting machine we purchased at Golden Laser on July 1 has now been installed and debugged. After-sales engineers and business service attitude are very good, and the training is very serious. Responsible, the cutting effect and speed are great! Golden Laser is a conscientious enterprise worth choosing!

Customers feedback that the processing quality is very good, and the Golden Laser fiber laser tube cutting machine is still very good! The price is affordable. After all, the market positioning is mainly center power laser cutting machine, but the company's service and attitude are still very good.

I am a South Korean sheet metal processing company. I purchased two 2000w fiber laser cutting machines for tubes from Golden Laser last October. It has been a year without any major problems. After-sales technicians often come to us. Worry-free after-sales.