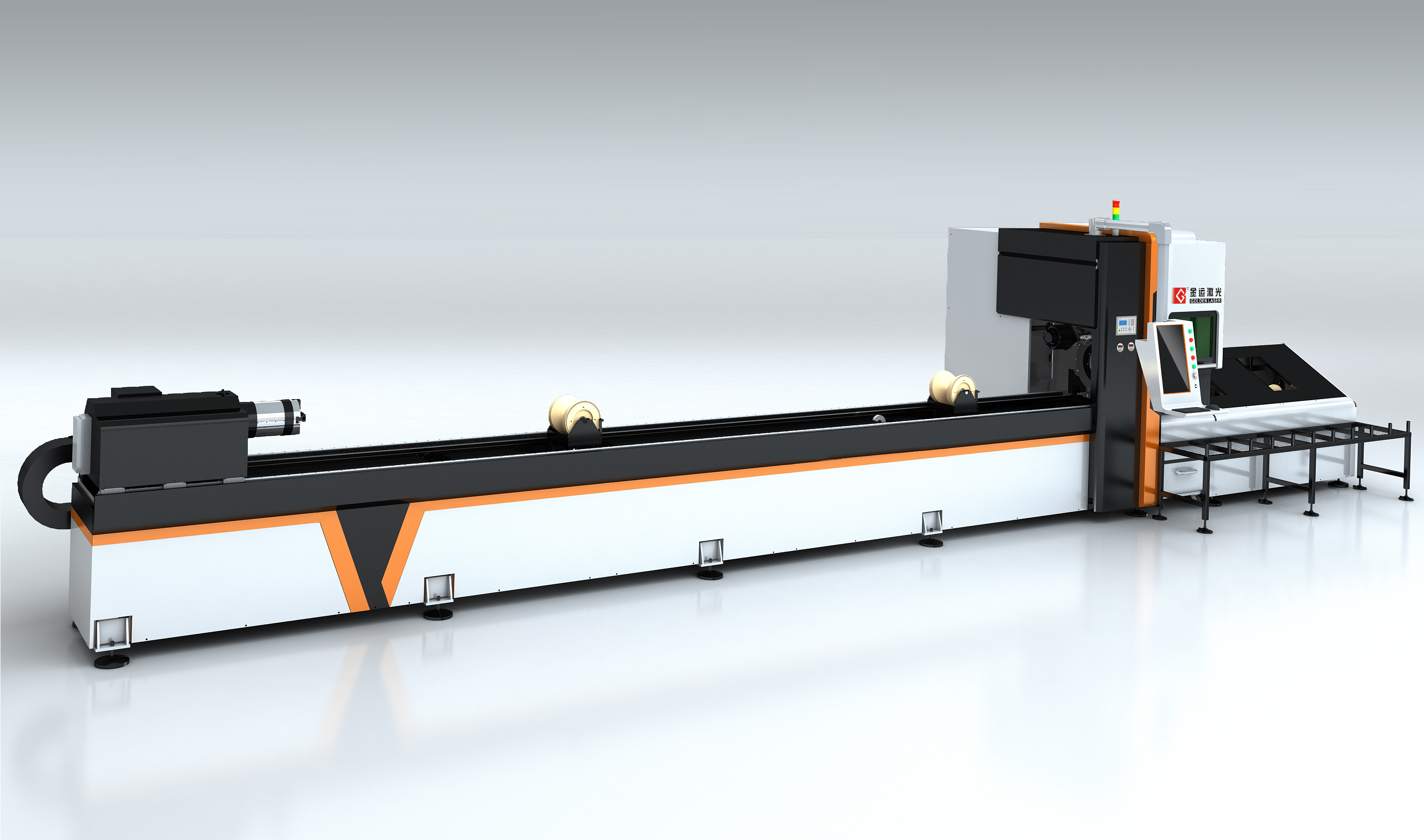

Cost-effective fiber laser tube cutting machine F20, your start-off laser tube cutting machine. It is an affordable, practical, and versatile tube laser cutter machine. The most productive fiber solution for your metalworking business. Tube ∅ Range min. 20 - max. 200 mm.

F20 laser tube cutting machine can not only cut round tubes, square tubes, elliptical tubes, but also can cut any tube shape such as channel steel, I-beam, and special-shaped tubes.

Compared with the laser pipe cutting machine with almost the same processing capacity, the cost can be reduced by 50%.

No NC code program is needed, just import 3D graphics to start operation.

● 1 tube laser cutting machine >3 sawing machines+ 2 punching machines

● It's the best entry-level metalworking tool

● A large plate welding bed is stable and durable for more than ten years

| Model name | F20 |

| Workpiece length | 0- 6000 mm (19.8') |

| Tube diameter range | Φ10mm - Φ200mm; □10mm * 10mm - □140mm * 140mm; Channel steel 16#; I-beam 16# |

| Type of tube | Round tube, square tube, rectangular tube, angle iron, channel steel, etc. |

| Single tube bearing weight | 150kg (Φ200mm*8mm*6000m) |

| Laser source | IPG/ nLIGHT/ Raycus fiber laser generator |

| Laser power | 1500W 2000W 3000W |

| Repeatability | 0.03 mm |

| X Y axis maximum moving speed | 80m/min |

| Rotational speed | 130r/min |

| Laser Cutting Metals And Laser Powers | |||||||

| Material | 1000W | 1500W | 2000W | 2500W | 3000W | 4000W | 6000W |

| Carbon steel | 6 | 10 | 12 | 14 | 16 | 20 | 25 |

| Stainless steel | 4 | 6 | 8 | 10 | 10 | 12 | 16 |

| Galvanized steel | 3 | 5 | 6 | 8 | 8 | 10 | 12 |

| Aluminum | 3 | 4 | 5 | 6 | 6 | 10 | 16 |

| Brass | 2 | 3 | 4 | 5 | 5 | 8 | 10 |

| Copper | 1 | 2 | 2 | 3 | 3 | 4 | 6 |

The bus cutting system is integrated with the control, matching the bus high-speed servo motor and the standard configuration professional pipe nesting software.

● More stable processing and high efficiency.

● Lower equipment failure rate.

● Simpler equipment maintenance.

When cutting pipes in the diameter range of 10-200mm, there is no need to adjust the position of the jaws. F20 cnc laser tube cutting machine can cut any hollow metal pipe.

● Save time and labor when processing different types of metal pipes.

Optional configuration, automatic feeder to help your metalworking business.

● The processing end adopts variable-diameter wheel support to ensure a more stable cutting process for more extended and thinner pipes and avoid pipe bending and deformation;

● The tail end adopts variable-diameter wheel support to avoid inaccurate precision caused by excessive tail tube weight when processing ultra-long tubes.

The clamping force of the pneumatic chuck can be adjusted flexibly. It is not easy to deform when clamping small tubes and thin tubes, and it is stable when clamping heavy tubes.

● One-key clamping in place, more convenient and quick!

The length of the pipe can reach 6 meters, and the pipe diameter can reach 10-200 mm.

Golden Laser is one of the leading tube cutting machine suppliers, providing cutting-edge solutions for various industries. Here are some advantages of Golden Laser's metal pipe cutting machine:

Golden Laser utilizes state-of-the-art laser technology in our tube laser cutting machine. The machines are equipped with high-power lasers that offer exceptional precision and efficiency in cutting metal pipes and tubes.

The pipe cutting machines produced by this pipe laser cutting machine manufacturer are designed to handle a wide range of materials, including steel, stainless steel, aluminum, copper, and more. This versatility makes us suitable for diverse applications across industries such as automotive, construction, oil and gas, and furniture manufacturing.

Golden Laser offers metal pipe cutting machines at competitive laser machine tube price, ensuring affordability without compromising on quality. Our favorable price of fiber laser cutting machine makes their machines accessible to a wide range of businesses, making it a cost-effective option.

As a professional fiber laser tube cutting machine supplier, we understands that different industries have unique requirements. Our lazer cutting machine for pipe can be customized to meet specific needs, such as laser power, pipe diameter, cutting length, and other parameters. This flexibility ensures that the3d pipe cutting machines can adapt to different production environments and deliver tailored solutions.

FSCUT5000 series is a bus cutting system specially launched for low-cost tube lasers. With the tube nesting software TubesT, it can realize various tube cutting processes such as co-edge cutting and supports online graphics import and drawing of the system, which saves time and materials.

Simple Auto Feeder:

It can be matched with a simple auto feeder to realize semi-automatic feeding, improve efficiency and save labor.

Industrial Robot:

It can automatically collect and stack the processed workpieces through a matching 3D robot arm machine, improving production automation capabilities.

● Digital system control ensures accuracy and flexibility. The laser tube cutting technology can produce any shape that has been programmed and cut in any direction.

● Engineers can quickly change the shape of the template without the help of any tools. The design can be modified at the last minute and will not affect the whole production process.

● End users can control short or medium version production without making a large number of templates, which can respond more quickly to customer needs, making it possible to achieve personalized customization.

Mechanical Cutting Machine

Mechanical cutting uses power-driven equipment to form and shape the material according to a predefined design.

Generally, mechanical cutting, punching, advanced laser cutting, and so on are used in the cutting process.

In small-batch, mechanical cutting is mainly used, such as turning, milling, circular saw cutting, grinding wheel cutting, etc. The main problems are low production efficiency and sizeable environmental pollution.

Laser Tube Cutting Machine

As an advanced processing tool, laser cutting machine is gradually entering the tube cutting market. Laser cutting technology is a technology with high production efficiency and firm productivity.

● The whole series of products have realized the modular design and free combination.

● Precision CNC fully automatic laser tube cutting. High precision, high efficiency, stable and reliability.

● Intelligent management system, robust process database to achieve high-quality processing.

● Strong expansibility, flexible processing of all kinds of pipes, profiles, and special-shaped pipes

Solid-state Laser Tube Cutting Machine

Compared with CO2 laser, a solid-state laser tube cutting machine has a lower operating cost and higher cutting speed. Early fiber technology could only cut at a higher rate on thinner materials. Still, with the emergence of higher-power lasers, fiber lasers showed a high cutting speed even in materials with a thickness of 0.5 inches. As a result, although the price of a solid-state laser tube cutting machine is high, it will still be a popular choice. Similarly, fiber technology can cut reflective materials such as brass and copper, but it is difficult for CO2 lasers.

Traditional CO2 Laser Tube Cutting Machine

In the past two decades, CO2 lasers have been the leading force in the metal manufacturing industry. These lasers work by making electrical energy flow through gas-filled resonators and using mirrors to focus and transmit light beams. In fiber lasers, diodes are used to create lasers, guided and amplified by optical cables, similar to those used in the telecommunications industry. Some applications are still more suitable for CO2 lasers, such as those requiring good edge quality on thicker or unique materials.