Job shops are typically manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs.

Job shops machines are aggregated in shops by the nature of skills and technical processes involved, each shop, therefore, may contain different machines, which gives this production system processing flexibility, since jobs are not necessarily constrained to a single machine.

What are the customer requirements?

1. The tubes used in the automotive industry, the processing method is mass automated processing;

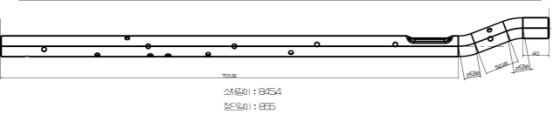

2. Pipe diameter 25A-75A; 8 meters of rough pipe;

3. Tthe length of the finished product is about 1.5m

4. After the laser tube cutting process is completed, the robot can directly grab the finished product for subsequent bending and stamping processing;

5. The maximum processing speed is not less than 100 rad/min

6. No burrs

7. The roundness of the pipe after cutting is close to a perfect circle.

How Golden Laser meets Hyundai Motor Company's requirements?

Customized 8m fiber laser tube cutting machine and automatic feeding system

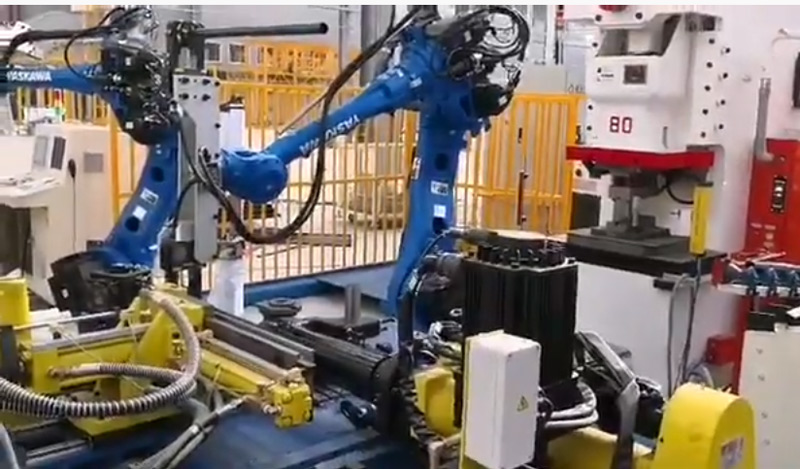

2. A robot is added to the receiving end to pick up. In order to ensure the accuracy of the subsequent process, the robot needs to clamp the pipe before cutting a single workpiece, and then cut it.

3. After being cut, it is transported by a robot to punch and bend.

4. Drill holes for elbows with a 3D laser robot

Industry 4.0, automation and digitization change traditional factories, welcome to get free customized smart factory solutions to boost your business!