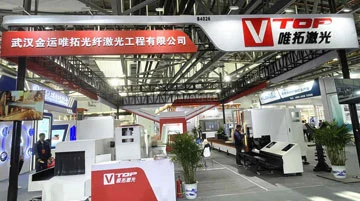

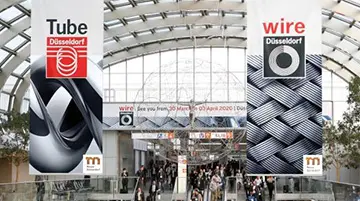

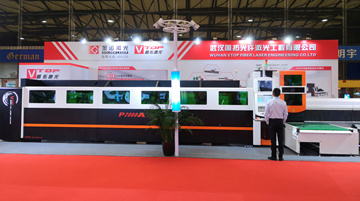

Golden Laser Will Meet You at EMO Hannover 2023

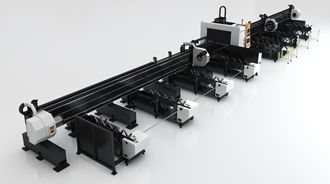

EMO Hannover 2023 world tour, the world’s leading fair for production technology, is coming to you. At EMO Hannover 2023, Golden Laser aims to engage with industry professionals, providing them with firsthand experience in laser cutting and welding technology.